Aergels are highly phased structured materials, the internal voids of which are filled with gas. They have very low density and thermal conductivity, as well as high hardness and transparency at the same time, due to which the aerogels are used for thermal insulation and other tasks. However, one of the key stages of obtaining airgels is a supercritical drying - very expensive, which limits the possibility of using these materials.

In the new work, scientists from the PCTU named after D. I. Mendeleev showed that, optimizing technological conditions for the supercritical drying, it is possible without deteriorating the quality of the material to significantly speed up this process and reduce the cost of the drying agent, which makes the synthesis of aerogels more affordable. The results of the work are published in the journal Drying Technology.

An ordinary gel is a three-dimensional mesh frame with a large number of pores filled with liquid. Aergels differ from conventional gels in that the liquid phase in them is completely substituted with gaseous. They have small density and at the same time high hardness, transparency, heat resistance, as well as extremely low thermal conductivity.

Therefore, airgels are used for the manufacture of thermal insulation materials, in various medical purposes and even in space - from them traps for cosmic dust, capable of capturing the smallest particles. Airgels are obtained in several stages: first of the basic chemical components make precursors solutions, then ordinary gels are obtained, and then the gels are dried, while the liquid, filling pores, is replaced with gas.

The usual drying at atmospheric pressure and elevated temperatures is not suitable for these purposes: it destroys the structure of the source gel and as a result of the aerogel from it not to receive. Instead, supercritical drying is carried out, in which supercritical fluids are used - so called the state of the substance at a pressure and temperature above the critical when the difference disappears between the gas and liquid phase (for example, conventional water becomes supercritical fluid at a temperature and pressure greater than 647 k and 218 bar, respectively).

The most common supercritical drying in the CO2 medium is most common (critical parameters: 303.9 K, 73 bars). During such a drying, the supercritical fluid gradually displaces the solvent, and then the pressure is reduced in the reactor, and the supercritical fluid goes into the gas phase - so from the gel in the end the airgel with a non-damned pore system is obtained from the gel.

However, the supercritical drying is very expensive, which limits the possibility of using airgels and materials based on them. Therefore, scientists are looking for ways to optimize this process. "Many scientific groups are engaged in the intensification of the process of supercritical drying," says one of the authors of the work, an employee of the PCTU, Pavel Gypsy. - We concentrated in our work on the effect of the process parameters - temperature, the consumption of the supercritical drying agent and its feed mode, to the key characteristics of the drying process - its duration and total expenditure of the drying agent.

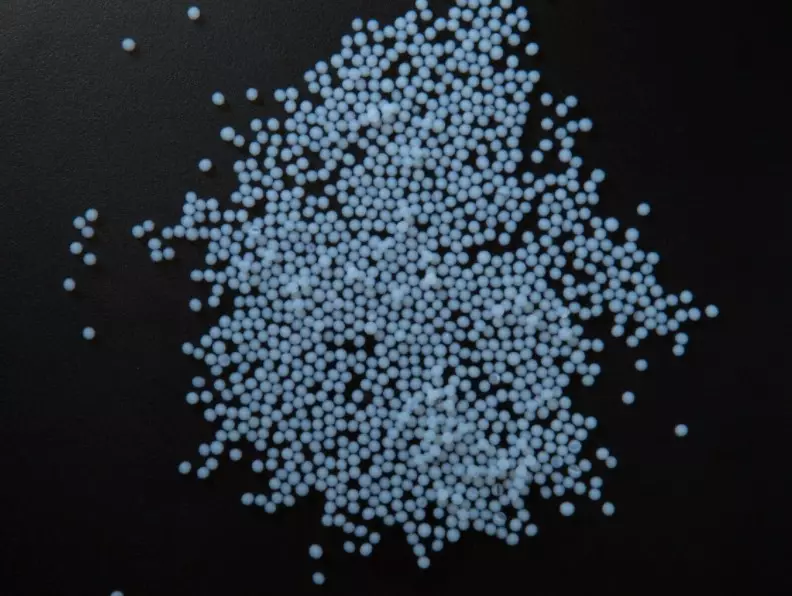

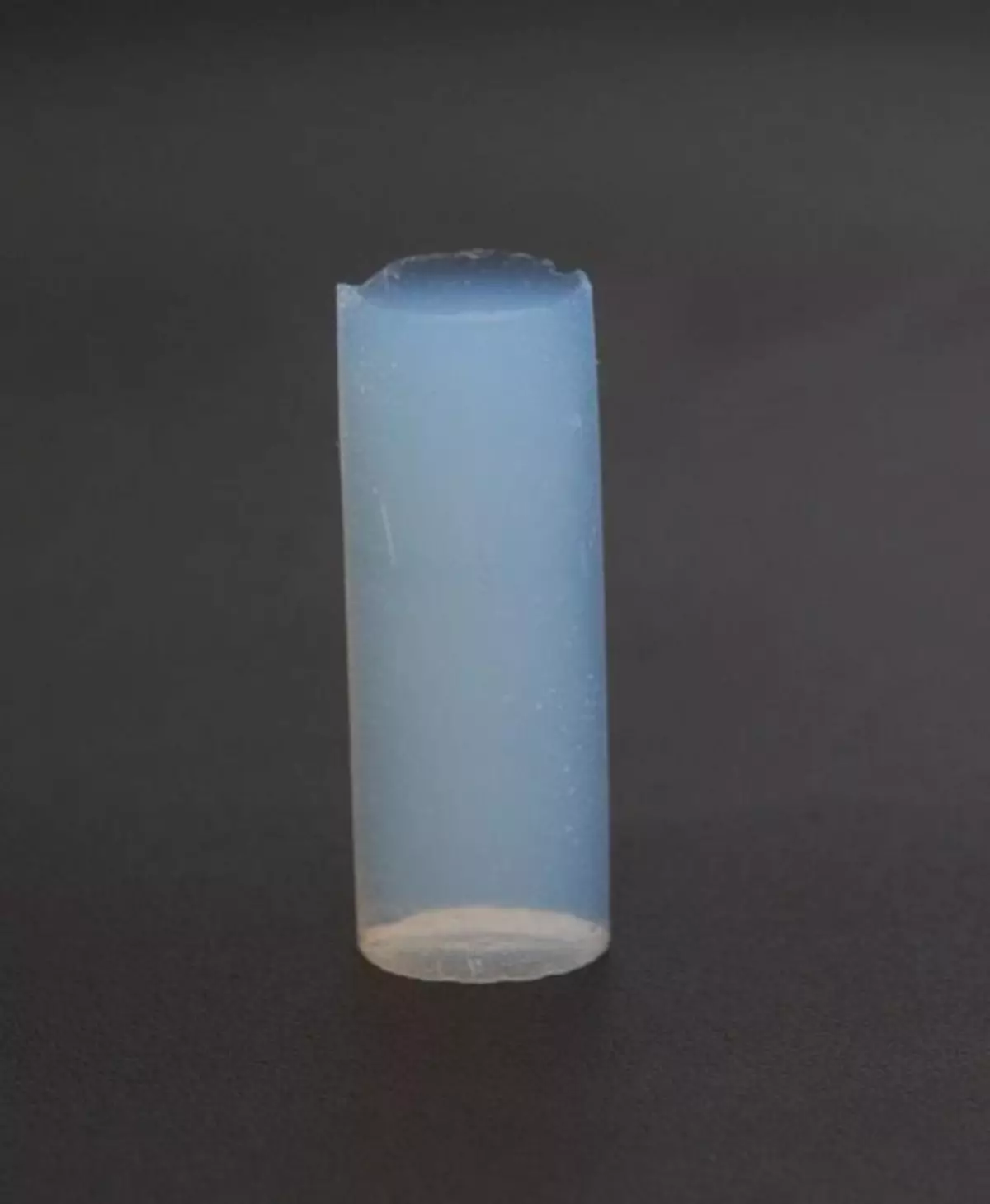

The researchers studied the process of supercritical drying using the example of classical aerogel based on silica. Isopropanol was used as a starting solvent, as a desiccant - supercritical carbon dioxide. All experiments were carried out in high pressure apparatus. Scientists ranged the main parameters of the process, trying, on the one hand, accelerate it and reduce the consumption of the drying agent, and on the other, do not worsen the product quality estimated by the residual content of the solvent inside the aerogel.

As a result, scientists found that due to changes in the parameters of the supercritical drying, the consumption of carbon dioxide can be reduced by 63.4 percent, and the total process time is about 50 percent. In this case, the quality of the produced product remains almost unchanged and the resulting silica aerogels have a developed specific surface area (about 850 m / g) and high porosity (about 95 percent). Thus, Russian chemists have found a way to optimize the process of supercritical drying, which is a substantial part of the cost of production of airgels.

Source: Naked Science