Two-photonic laser lithograph (DL) is one of the main directions in the development of additive technologies used to create polymer micro- and nanoobjects. Its unconditional plus is the ability to create structures of almost any three-dimensional configuration, which can be used when creating photon crystals, waveguides, various mechanical devices, as well as in processing and storage devices.

However, despite the excellent opportunities provided by this technology, it contains substantial limitations. The choice of materials when using DLL is limited by photoresists - polymeric photosensitive materials. Due to the transparency of polymers in the visible range, the lack of electrical conductivity, mediocre mechanical properties, as well as low heat and radiation stability, the practical use of structures created with DLL remains limited. It is possible to overcome some of the existing restrictions using post-processing of DF-structures.

One of the promising methods of post-processing is called pyrolysis, which simultaneously provides both an increase in the resolution and the introduction of new functionality. In particular, pyrolycred materials demonstrated high thermal and radiation stability along with increased mechanical strength. DLL followed by pyrolysis is already successfully used to obtain carbon nanoelectrodes for neurotiator sounding, special tips for atomic-force microscopy, photon crystals in the visible range and superproof mechanical metamaterials.

Pyrolysis also improves the resolution of the DLL method, since the structure exposed to pyrolysis, showed a significant shrinkage compared to the original size. But the shrinkage of pyrolyzed structures aggravates the problem of adhesion structure to the substrate arising already in the DLL stage. These problems are important practical importance, but so far there were no comprehensive research on these issues. Meanwhile, the correct assessment of the decrease in the size of the elements and in general the comprehensive assessment of the impact of pyrolysis on the DF-structure is absolutely necessary if there is a task of getting mic processing with high accuracy.

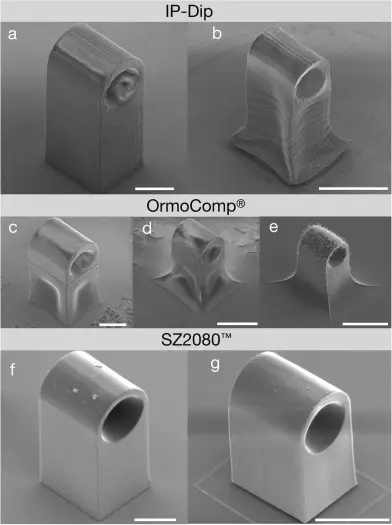

Top row: IP-DIP (a) lens (a) to pyrolysis and (b) after pyrolysis at 450 degrees C. Middle range: ORMOCOMP (C) lens to pyrolysis and after pyrolysis in (d) 450 degrees C and (E) 690 degrees C . Lower range: Lens SZ2080 (F) to pyrolysis and (f) after pyrolysis at 690 degrees C / © www.osapublish.org

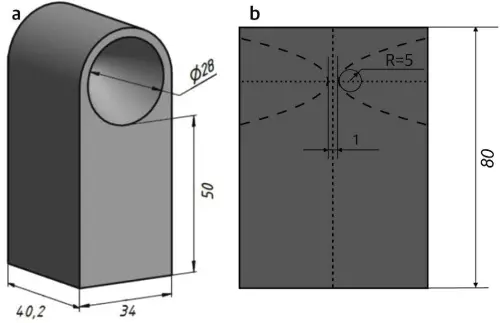

Scientists of the nanofotonic sectors of the center of quantum technologies MSU set themselves the task of conducting a comparative study of the influence of pyrolysis on solid objects in the size of dozens of micrometers, printed using DLL technology from three commercially available photoresists: Fully organic IP-Dip and organ-inorganic ormocomp and sz2080. For annealing temperatures 450 and 690 degrees Celsius in an argon atmosphere, changes in the size, chemical composition and adhesion to the substrate of the silicon plate were estimated.

In the work published in the Optical Material Express journal, the CCC scientists confirmed that the shrinkage of the structure is determined by the type of photoresist, as well as the pyrolysis temperature, atmosphere and geometry structure. Taking into account the behavior of a particular photoresist after post-processing with pyrolysis, it is possible to achieve optimal results, fully corresponding to the specific tasks, and create wear-resistant and reliable micro- and nanostructures of arbitrary shape and almost any destination.

Comparison showed that a higher temperature leads to a stronger shrinkage. Structures from IP-DIP after annealing are converted into glass carbon, while the inorganic substances of the ORMOCOMP and SZ2080 photoresists are modified in the glass with annealing. Structures from IP-DIP also demonstrate the largest shrinkage from the selected photoresists. Thus, the DLL with the subsequent pyrolysis of the IP-Dip pyrolysis can be used to create conductive glass carbon structures.

ORMOCOMP is useful for the creation of ordered arrays of optical elements that can be in demand on X-ray sources. In turn, the structures from the photoresist SZ2080 during pyrolysis are often disconnected from the substrate, which is convenient for the manufacture of single structures, which then need to be moved to another Wednesday. The obtained data may be further used using pyrolysis technology as a standard method of post-processing structures created by DLL technology, and will serve as an active development of this type of post-processing, scientists note.

Source: Naked Science