Ribbon foundations are grounds under structures with small dimensions and mass. If the concrete foundation is to strengthen the reinforcement, then you can significantly increase the freight and strength characteristics of the base. The reinforcement process itself is not difficult if you comply with simple rules and recommendations.

In this article, we will examine all the nuances in detail, related to the technology of strengthening the ribbon foundation of reinforcement, as well as characteristic errors in this process.

Production of ribbon foundation

The ribbon foundation received such a name due to the design of the concrete structure. The foundation is placed only in contours of outdoor walls and internal partitions. If with the foundation to demolish all the upper superstructures, then the base will completely repeat the contour of the house.The production of a ribbon foundation is performed in the following sequence:

- Marking of the territory and contour for mounting formwork.

- Ground removal to a depth of no more than 40 centimeters.

- Strengthening the bottom of the gauge with a sand pillow and a layer of waterproofing (polyethylene film).

- Installation of formwork to the height of no more than 40 centimeters.

- Preparation of reinforcement frame.

- Pouring a concrete mix.

- Waiting for monolith solidification.

A separate stage of the construction of a belt foundation is its reinforcement. We will analyze this event in more detail.

Features of the use of fittings

The reinforcement is customary to call metal structures that are assembled from a rod rod. The diameter is selected according to the scale of the design of the whole monolith.

The use of reinforcement has a positive effect on the following characteristics of monolith:

- Increases durability. Reinforcement increases the service life of the foundation for 10-15 years.

- The limit of painting and destruction under the weight load increases.

- The foundation increases freight characteristics and more evenly distributes a mass of structures on the ground.

- The reinforced foundation is not destroyed by freezing.

It should also be noted that the use of metal structures in the manufacture of grounds leads to an increase in the cost of production by 1/3. But expediency is to increase the characteristics that will allow the whole building to last for 10-15 years longer than the established period. Economic useful effect is obvious.

Ribbon Fundament Reinforcement Technology

Reinforcement is a technological process that requires compliance with all rules and rules. First of all, it is necessary to prepare the reinforcement scheme and calculate the number of materials.

The reinforcement scheme may be as follows:

- Laying fittings for the bottom of the foundation.

- Uniform frame reinforcement.

- Laying of reinforcement vertically.

- Combined reinforcement.

Each scheme should be said separately.

Staying fittings for the bottomAs a rule, this method is used in the "handicraft" construction of small structures, such as a bath or garage. For this, it is not necessary to use metal rods, it is enough to assemble the entire scrap metal on the residential area and use it.

The main thing in the process is to observe the rule - it is impossible to overstat the monolithol monolithol. It places directly on the bottom, on top of the insulating layer.

Armature carcassThe framework of the reinforcement is the design of the reinforcement in the form of a cube or a rectangle, which is divided into uniform cubes. The connection of the rods is made knitted (plinning) wire.

In order to make a reinforcing frame, the formwork is performed - its widths and heights. The cross section of the rods is selected, and after using the bending machine, the desired geometry is set. The frame is placed around the perimeter of the excavation in the ground.

After the formwork poured cement, which fills the reinforcement cells. So all the monolith will be permeated with a metal rod.

Vertical laying of fittings is required for foundations with local loads. Such loads arise in the event that a frontal timber or a chaserler is laid on the surface of the base, on which the bearing walls are mounted. In most cases, bearing walls are collected immediately "from the foundation."

At the bottom of the ground recess, a substrate from a light cement is performed, vertical tubes with a uniform step are installed in it. The substrate is frozen and the main fill of the concrete mixture is carried out.

Combines vertical reinforcement with frame. According to the technology, the process is similar to strengthening the foundation piles as painting, only instead of piles, vertical tubes are used. They are placed in accordance with the rules for laying vertical fittings. Up to half of the tube from the bottom of the formwork is mounted frame from the rod. The whole complex design is poured by concrete.

How to knit reinforcement from the rod?

A knitting wire is used to connect reinforcement rods, which has sufficient strength, but it allows you to deform and bend yourself for binding rods. The use of welding is extremely undesirable because:

- The joints connected by the melt of the metal are losing in strength by 50-75% of the initial value.

- Welding places are subject to corrosion, whose formation will lead to the destruction of the reinforcement frame.

It should be immediately noted that the use of the hook does not save from several hundred nodes, which will need to be made in the frame of even a small foundation.

To speed up the workflow, you can use a special gun for mating.

Plus, from its use - acceleration of work twice, but there is also a number of serious conventions:

- The price of a pistol is in the range of 40-50 thousand.

- For mating, a special wire may be required, the usual can rush.

The use of a qualitatively tool will allow only 1 day to make a high-quality frame from the reinforcement, which will have a positive effect on the quality of the construction.

Proper manufacture of reinforcement frame

For the frame of the reinforcement, there are not so much load from the mass of the house, but the exposure of the soil in the spring and late autumn, when the deformation of the melting and the freezing of the soil occurs. If the frame is accomplished poorly, the negative impacts can destroy the base in just 3-4 seasons.

The following rules are important in the manufacture:

- The distance from the rod to the place of the bunch of rods should be at least 5 cm. This distance is called naughty.

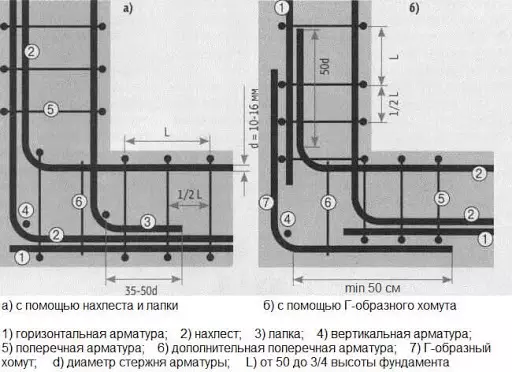

- Corner connections when the rod is applied to the rod perpendicularly, be sure to be fastened with wire. Locked ends are categorically prohibited. In order not to connect each corner of the wire, it is better to use fittings that bent under 90 degrees. For folding, you can use manual or automatic reinforcement.

- The valve must be tightly tightened. The movement of the ligament on the reinforcement is not allowed, the wire must fit tightly to the surface of the rod. If the nodes are manufactured with a crochet, then the wire is dragged until it stops.

- The reinforcement rod is placed on the Vannet perpendicularly, but under the condition that the length of the end is at least 50 diameters of the rod.

- The gaps between the reinforcement frame and formwork are not allowed.

Corners in the foundation are nodes to which the maximum carrier load turns out, in addition, they distribute it around

It is undesirable to bind the corner joints with the wire. For the frame in the corners, additional twisted rods are laid (as shown in the diagram)

For figs of reinforcement, a special tool is applied - armature boobs. They have a different design and modification.

Drive unitThe simplest devices have manual drive. The place of folding the rod is placed between two cams, the operator turns the armature gorogybiba and bending due to the lever. The performance of these devices is small, it is advisable to use in private construction.

Automatic bends are used to drive a rotary electric engine with a limiter. When grate, the rod is placed in the cams, the fold parameters are set, and after the automatic fold is performed. Such reinforcement flexors have high performance and apply on industrial and large construction sites.

ClassThe variability parameter of the armature production is divided by the diameter of the reinforcement:

- Up to 20 mm. - Light staves for private construction.

- Up to 40 mm. - Medium for the construction of high-rise buildings.

- Up to 90 mm. - heavy for the construction of large objects.

Characteristic errors in reinforcing a tape foundation

In reinforcement there are a number of errors that can become fatal for the foundation. Errors are associated not only with calculations, but also construction technology.

The following points include characteristic errors:

- No connection between reinforcement. The reinforcement rods that are stacked on the bottom must be laid by the Vangest or Crosshair. If they are placed simply, then with the time corrosion destroys the metal, the cavities will occur, which will be filled with condensate water from metal. The moisture will freeze and expand - this will lead to the destruction of the base along the bottom, which means the premises of the house or structures will begin to freeze.

- Using an insufficient number of reinforcement or erroneous selection of section. If for a massive foundation to use an insufficient amount of reinforcement or short cross section, it will lead to an incorrect distribution of the concrete mix when filling. Monolith will have uneven strength characteristics. It is dangerous in that with an uneven load of the mass of the house on the base - it can point point to collapse, which will bring to the collapse of the house by the facade.

- Making the reinforcement cell of a small cross section. Often, in the manufacture of a knitted frame, the cross-section of the square is so little that does not let the concrete mixture inside the reinforcement frame. It is necessary to observe the side of the square of at least 10 centimeters.

- Stitching tubes into the ground with vertical reinforcement. Often, for saving time and means in vertical reinforcement, the tubes are stuck directly to the ground. This violation of the rules of laying can lead to the pouring tubes when pouring concrete, the technology will not be observed, which means that the strength characteristics will not be increased.

- The use of squares of the square section when laying vertical fittings. The rods or tubes of the circular cross section allow a concrete mixture with an intense flow to telete the surface of the reinforcement evenly. Square cross section with a flat side may not withstand loads from the supply of concrete.

Concrete reinforcement is an important technological process of improving the strength characteristics of a concrete foundation. It is mistaken to think that it is impossible to fulfill the whole process. The knowledge that was received after reading this article will be quite sufficient to independently strengthen the foundation of reinforcement. The main thing is to comply with all the rules and carefully approach the workflow.