3D printing of alive fabrics, including cornea, blood vessels and skin, is not an easy task. But at least it is all living fabrics. Bone, on the contrary, is a mixture of alive and inorganic compounds in a highly structured mineral matrix. In other words, the bone for 3D printing is a challenging task.

That is why bio-engineers tried so many different materials for their synthetic bones, including hydrogels, thermoplastics and biocheramics. Recently, the team of the University of New South Wales (Australia) developed "ceramic ink", which can be used during 3D printing at room temperature using living cells and without the use of rigid chemicals, which significantly improved the situation compared to earlier technologies. According to the researchers, the new technology in the end can be used to print bones directly in the patient's body.

Information about this development was published in the Advanced Functional Materials magazine.

3D-printing of bone tissue has many medical and research applications - modeling of bone diseases, drug screening, study of unique bone microenvironment and, possibly, the most important thing is to restore damaged bones in case of injury, cancer or other diseases.

Modern gold standard for repairing bone is the use of bone transplant from another part of the patient's body. Unfortunately, the use of such grafts is associated with a high risk of infection and cannot be used if the required amount of bone material is too large.

In an attempt to create the necessary synthetic bone material, university scientists made ink, which can be printed in an aquatic environment, such as body. After two years of work, they created a biocompatible material based on calcium phosphate, which forms a paste at room temperature. When placed in the gelatin bath or another solution, a chemical reaction occurs, and the paste solidens into the porous nanocrystalline matrix, similar to the structure of the original bone tissue.

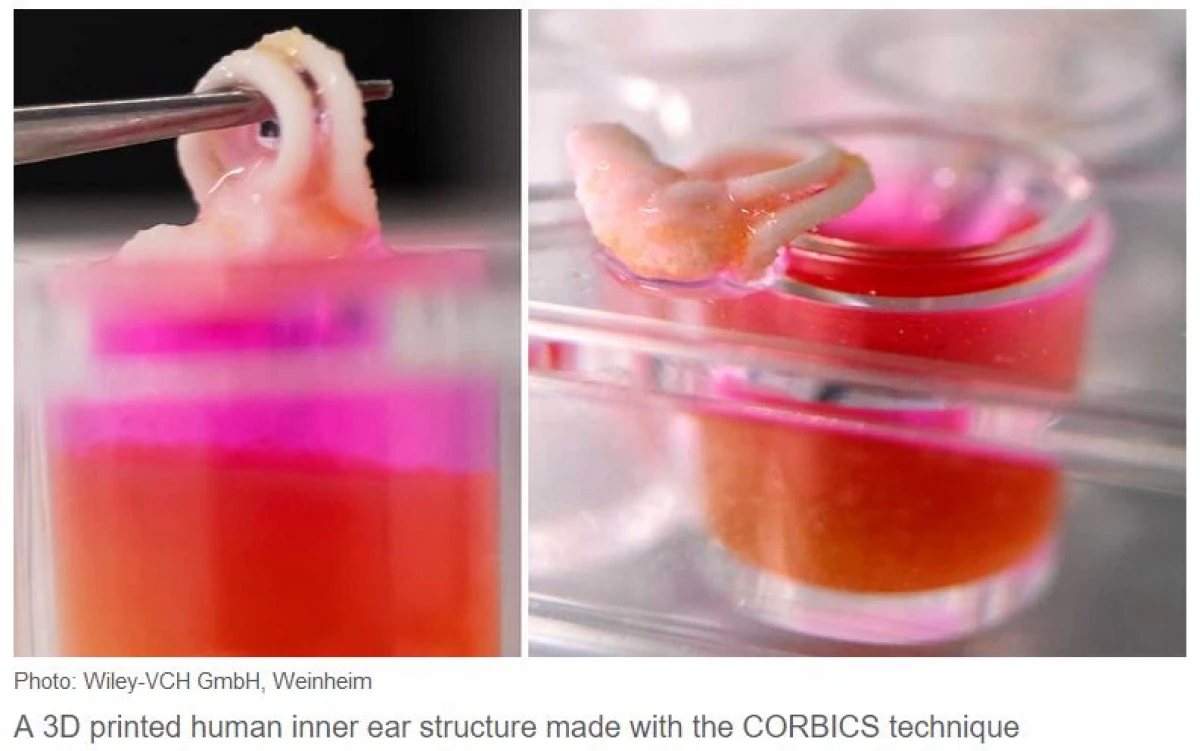

For printing, they used the standard 3D Engine HR 3D printer with a special Dueza. Small needles ranging from 0.2 to 0.8 mm extruded ink into the gelatin bath with a temperature of 37ºC. The technology called COBICS (Ceramic Omnidirectional Bioprinting In Cell-Suspensions) can be adapted to other 3D printers, such as portable and manual printers that can be taken with you in a surgical room.

In his recent work, scientists have printed small bone structures in the gelatin bath containing human bone cells and other types of human cells. The solidifying ink introduced live cells into the structure, and these cells arrived after printing and began to multiply. Survival efficacy was 95%.

Currently, the team develops a bath for printing larger samples and began conducting tests on small animals to check whether this technology can restore a large wound as efficiently as a lively transplant.