If you are engaged in soldering, work a lot with solvents and paints, then your workplace must be equipped with an extract. If you spend on it or materials for its manufacture, there is no desire and opportunity, then you can collect such a device mega budgetically from what is found in the house. The homemade extract will cope with its work 100%, the main thing is to equip it with a good fan.

Materials:

- plastic bottle;

- Food stretch film;

- fan;

- Corrugated cardboard.

Process of manufacturing corrugation and exhaust

It is necessary to pump a PET bottle, and warm it over the gas stove so that it straightened, more here -

After that, with the help of bottles, it is required to dissolve 8 mm wide on the tape. The ribbon tapes the spiral and heats over the stove. Then she twisted and stretches further. The resulting spiral is immediately discharged beyond the heating zone so that the plastic is not excessively soften. As a result, a tube must be turned out, a twisted turn to a turn without gaps and overlap. So it will be enough elastic.

The resulting tube should be examined along the entire length. The discovered clearances and adolescence on the turns must be cut. Cut edges glued with a thermoclaim.

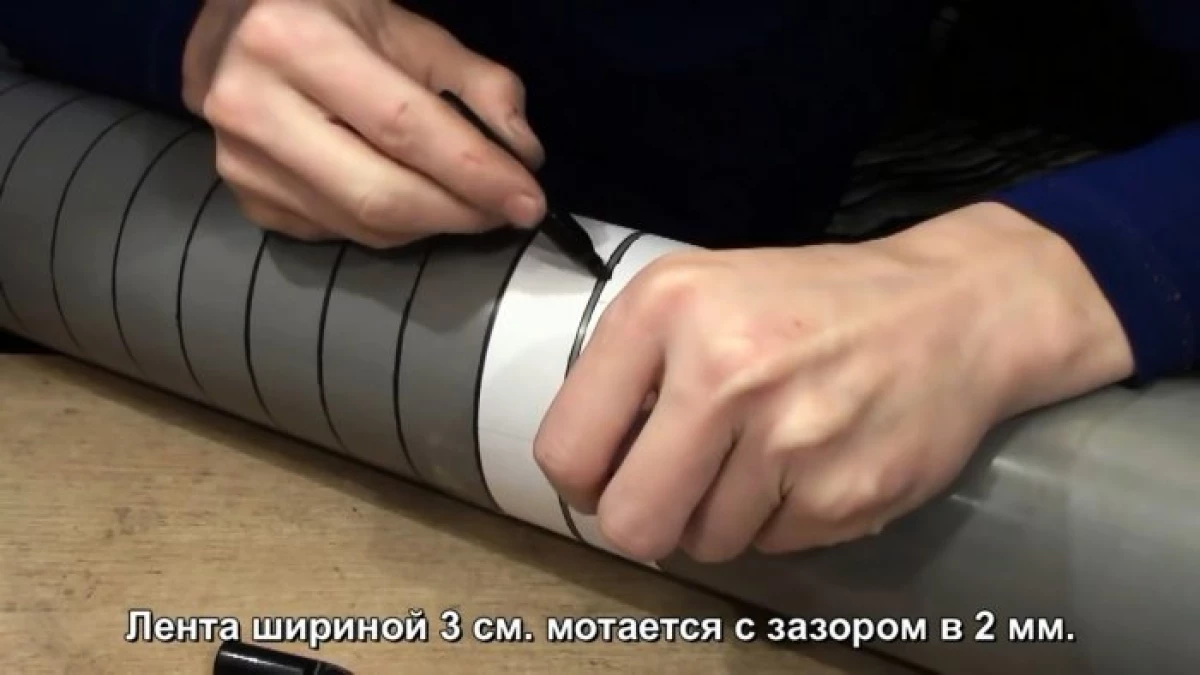

Next, the template for the corrugation is drawn. For this, the sewer pipe is ideal for 110 mm. The paper tape is wedged with a width of 3 cm. Between her turns is made 2 mm gap, and it will be worked out with a marker.

The tube from the bottle is wound on the sewer pipe. From one edge it should be grabbed with glue. Next, it is powered by boiling water to take the tube.

After that, the tube is wound with the painter on the marker. At the beginning of the winding is made 2 straight turns. They must be reclined in two places. The last turn is also glued.

The tube will serve as a frame for corrugations. Next you need to wind the stretch film on the sewer tube. The first round is made without tension, then 3 with a stretch of film by 5-10%. Watch should be smoothly. Then the desired part is tightened, it is left on the pipe 3 turns and everything is repeated again with the allen on them. So you can make the corrugation of any length, at least 10 m.

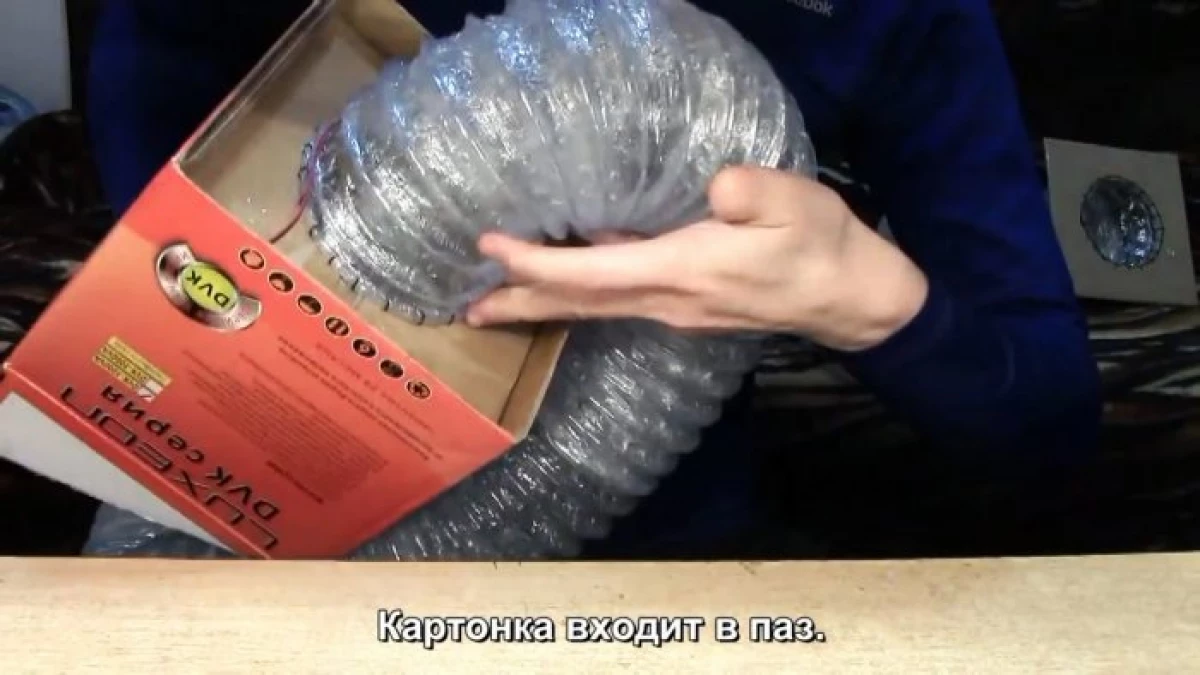

Cardboard linings with holes are sewed to the corrugation on the edges. It is best to glue them from a pair of cardboard layers so that they are hard. Then one end of the sleeve is installed fan.

The drawer is made from the cardboard box and joins the second edge of the corrugation. Now, when the fan is turned on, the air with evaporation and smoke will be sued inside, and the outward from the working area is given.