For refining steel and protection of it from corrosion, it is coated in various ways. It can be the creation of an oxide film, spraying, etc. Most of these methods are too technologically, to repeat them at home. Consider the coating options for steel, which can be done with your own hands.

Application of brass coating

Steel workpiece must be pasted. The final processing is performed by sandpaper at least P180.

The billet is degreasing.

After that, the plates are heated by the gas burner to the straw color of the breakdown, and is preparing a brass brush for metal.

As a result, the treated surface will look like a brass.

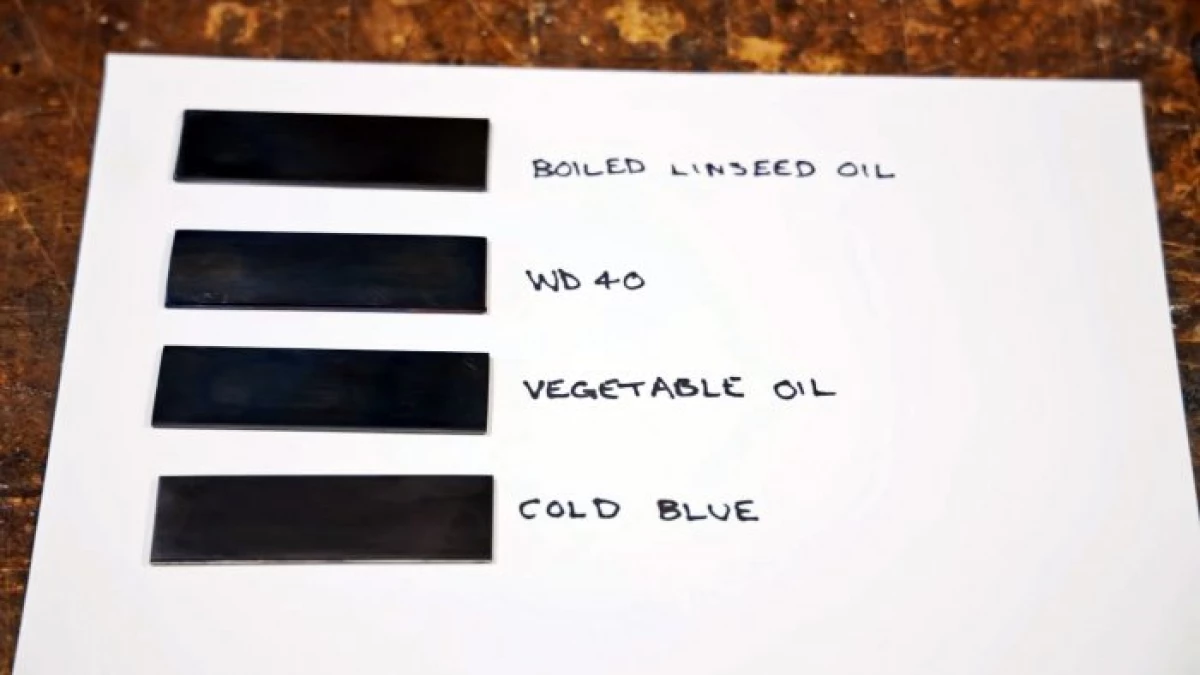

Normal Dark Black Linen Oil

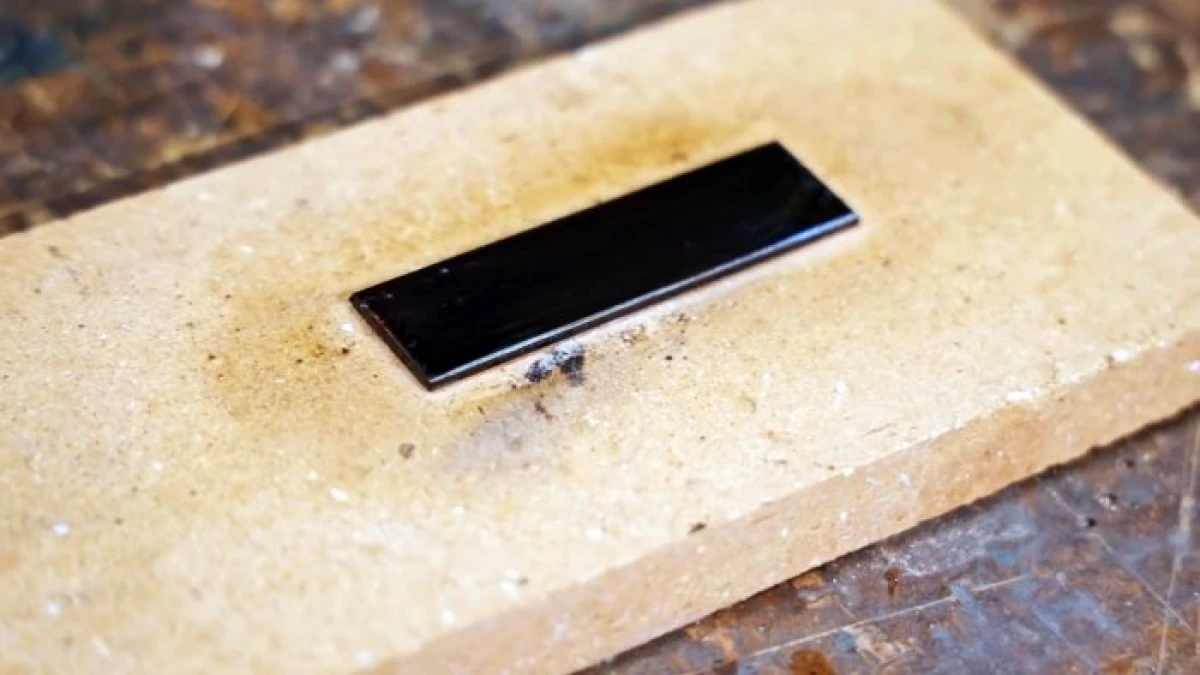

The billet is grinning and degreased. Next, it is necessary to heat the burner to the color of running between straw and blue, maximum to gray.

After that, the hot surface is wiping with flaxseed oil or dip in it, if it warmed up evenly.

Then the remains of the oil are survived and erased.

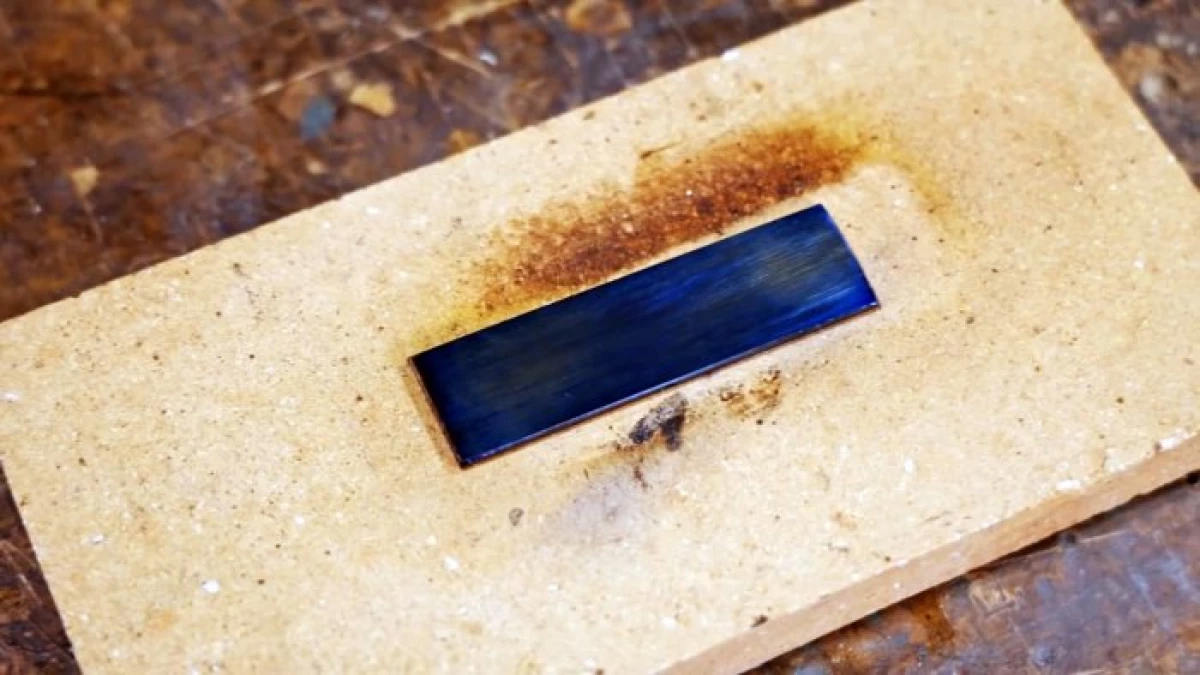

Blue shade

Prepared in a similar way, the workpiece is heated to the blue of running. Immediately after that, WD-40 splashes on it. As a result, the steel will become blue.

Sunflower Oil Burning

If you warm up the workpiece to the maximum to gray break and dip in sunflower oil, then the blackness will turn out to be gray. It looks not bad, and is being done easier.

You can wipe the part of acetone, heat again and dip in the oil, then it will become darker. The result will be similar to black with oil overlooking.

Cold Burning

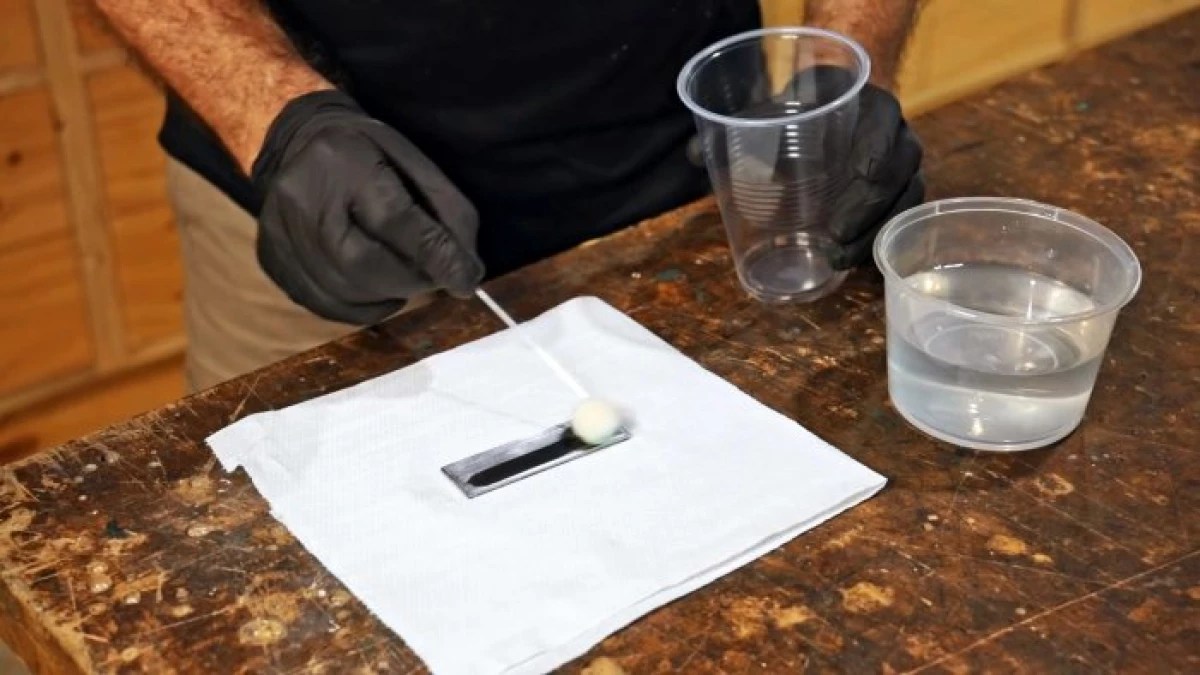

Also on sale you can find special compositions for cold boring.

Their advantage is that the surface is obtained more uniform in color. Such formulations are applied according to the instructions. Usually rubbed for metal, and after 30 seconds are washed off.

If the borders or the application of the brass layer is performed in decorative purposes, for example, on steel parts of furniture and interior items, it is advisable to open them with varnish. So the coating will last decades.

Watch the video

See how you can perform the steepness of steel - https://sdelaysam-svoimirukami.ru/6666-voronenie-mednenie-v-domashnih-uslovijah-i-gde-jeto-mozhet-prigoditsja.html