Ho ithuta ha bo-ramahlale ba Perm Polytechnicnic ke ho thusa ho eketsa sesupo sa marokho. Ba ne ba ithuta kamoo lisebelisoa tse tsoang ho likarolo tsa likarolo tsa bona lia itlhahisa tlas'a ketso ea tikoloho ea kantle. Sena se tla qoba ho putlama ha marokho le ho fokotsa litšenyehelo tsa lichelete le tsa nakoana bakeng sa ho lokisa.

Bo-rasaense ba phethile mosebetsi oa lichelete ba tšehetso ea lichelete tsa thuto ea bohlokoa ea Russia. Liphetho tsa mosebetsi li phatlalalitsoe ho IOP Sechabeng: Lisebelisoa tsa Saense le Boenjiniere, Tsoelo-pele ea Buka ea Setsoalle: Science Science le mahlale a hokahaneng.

"Palo ea likoloi le literene li tsamaisang selemo se seng le se seng ea eketseha, 'me litlhoko tsa lintlha tse ikarabellang tsa marokho le tsona lia eketseha. Likarolo tsa litšupiso li na le meroalo e sa feleng ho tloha ho nako ea borokho, li tlasa ts'ebetso ea keketseho le coffincheng, shrinkage le Setsimic Purtritions.

Ho holisa bophelo ba marokho, lisebelisoa tsa se fapaneng tsa kajeno le liqapi li sebelisoa e le karolo ea likarolo tsa bona tsa litšupiso. Empa ponong ea mahlale a mahlale, profinse ea bona ea "boitšoaro" ha ea lekana, Mechanis

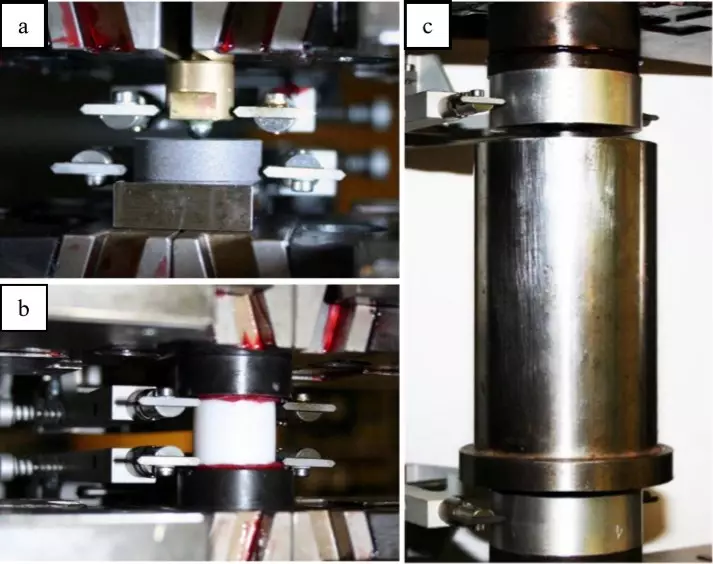

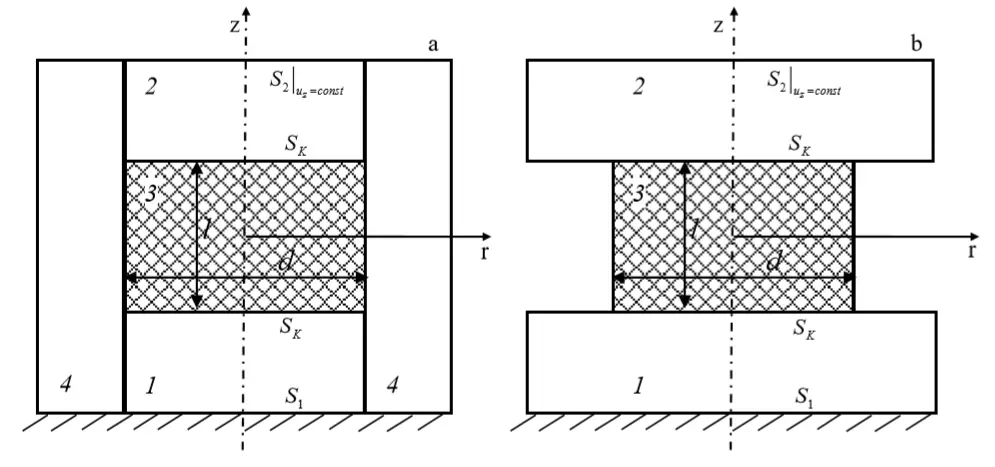

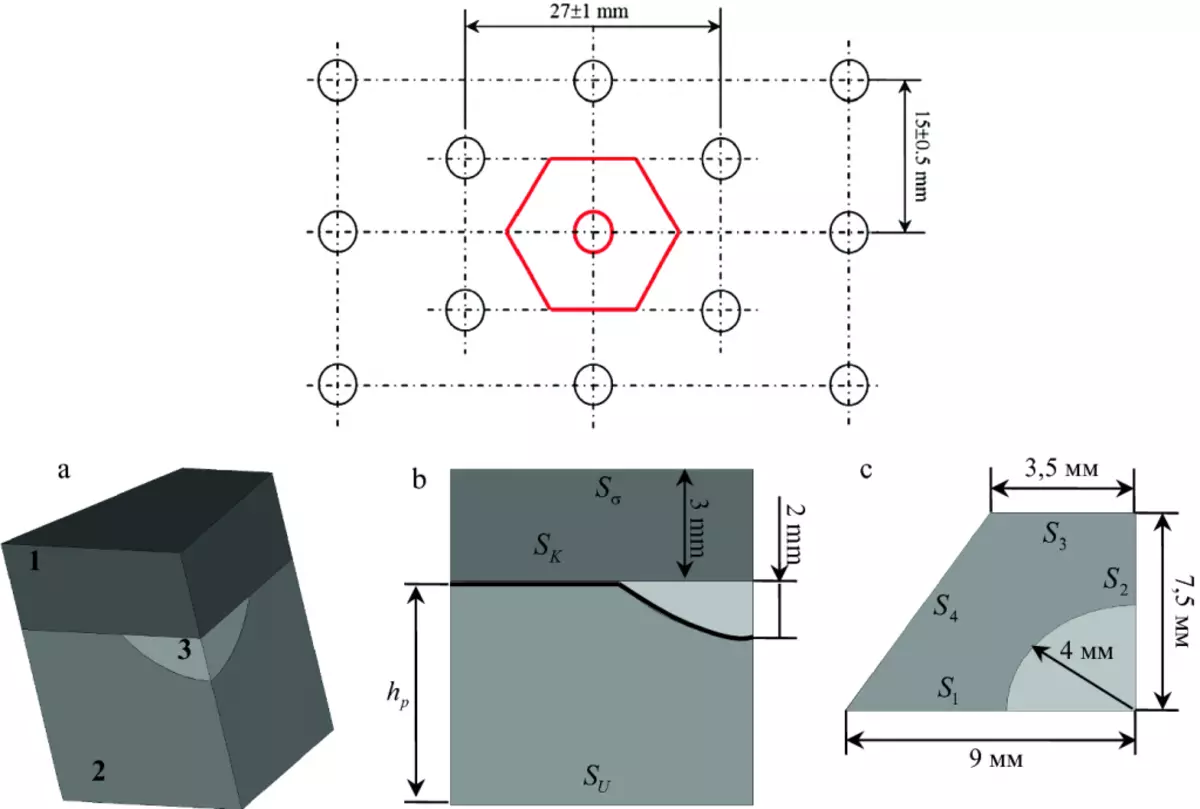

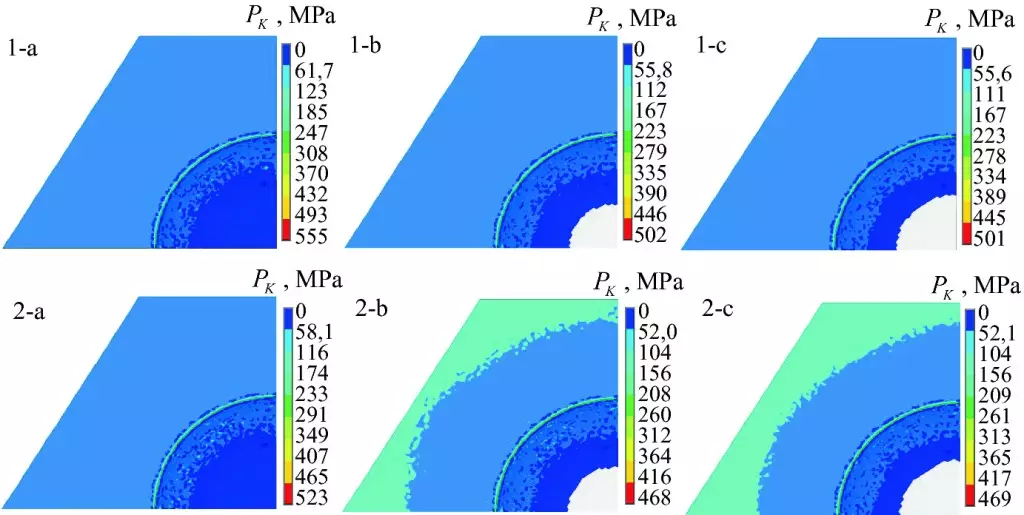

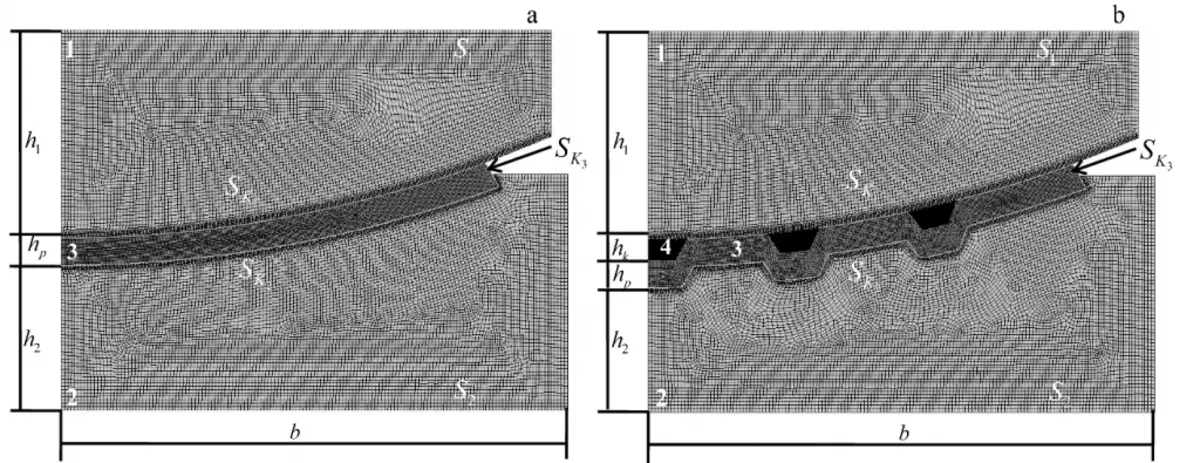

Bo-rasaense ba ile ba etsa lipatlisiso ka "boitšoaro" libakeng tse tšehetsang tsa marokho a nang le polymer tse fetang 30 tse tšehali. Ka ho khetheha, ba ne ba ithuta ho boima ba lipalesa tsa 'mele ba molek'hule polyethylene, e fetotsoe flores. Ho sebelisa mofuta oa lipalo tsa Paramente karolo e bulehileng ea borokho, bafuputsi ba ile ba tseba hore na sebopeho sa thepa le thepa ea lisebelisoa li ama deformation le joang.

Ba bapisa likarolo tse tšehetsang tse nang le likarolo tse nang le bophara ba limilimithara tse 4 ho isa ho tse robeli. Bo-rasaense ba fumane hore keketseho ea karolo ea mithara e ka bang 6-8 e fetohile boima ba 'mele bo boholo le bo phahameng ba lipalesa tsa polyethylene.

Bafuputsi ba ile ba ithuta likarolo tse tšehetsang tsa marokho ka lebaka la tlhahiso ea Alfatekh, e ileng ea qala ho thahasella morero. Liphetho tsa mosebetsi oa bo-rasaense ba polytechnic ea Permcinian li se li sebelisoa ho moralo oa likarolo tse ncha tsa meaho ea Bridge. Liphetho tsa batho ba bang le ba liteko le ba bong bo tla thusa ho ntlafatsa meaho ea marokho.

"Mehlala ea Boitšoaro ba Lihlahisoa Tlas'a ketso ea tikoloho ea kantle e ts'episa bakeng sa ho se sebelisoe eseng feela ka ho aha, empa hape le ka mochini, indastering ea moea le ea koloi. Ho feta moo, li ka sebelisoa ho biomechanics le meriana - ka mohlala, ha re etsa "boitšoaro" ba lengole.

Mohloli: Saense e hlobotseng